For the first time in years, Apple increased the entry price of new iPhones with the iPhone 8. The 64GB iPhone 8 is priced at $699, which is $50 more than the 32GB iPhone 7 or the 16GB iPhone 6s that were the cheapest iPhones in previous years. The same goes for the iPhone 8 Plus, which retails starting at $799, or $30 more expensive than the iPhone 7 Plus last year. The higher capacity models, however, are priced just like their 2016 equivalents.

Why does a new iPhone cost more than it used to? A new teardown offers us the answers.

iFixit may be the teardown authority when it comes to do-it-yourself repairs, but it’s IHS’s teardowns that tell us how much it costs to manufacture an iPhone.

Just like every year, the company released its findings on the matter, concluding that both the iPhone 8 and iPhone 8 Plus are more expensive to make, which explains why Apple hiked the base price by up to $50.

The iPhone 8 Plus components cost $288.08, while manufacturing adds a $7.36 for a total of $295.44. That’s $17.78 more than the iPhone 8 Plus. Comparatively, the iPhone 8 bill of materials os $247.51, $9.57 higher than the iPhone 7. Costs for software and research and development aren’t factored in these estimates.

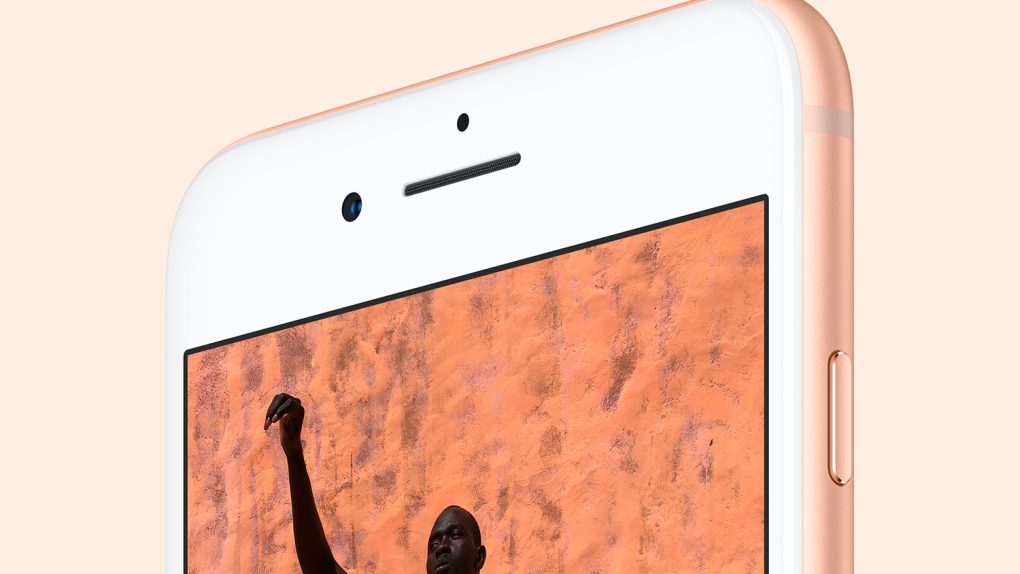

IHS told Bloomberg that the iPhone 8’s biggest improvements concern the camera, memory, and processor.

“The added value went to memory, camera, and processing. That’s where we can materially identify where they’ve improved the overall product, and hence why they can command a higher price for it,” IHS analyst Wayne Lam said.

Screens, mechanical enclosures including the glass back are the most expensive iPhone 8 components. The added wireless charging parts also increased power-management costs by $2. The larger storage capacity costs $6 more per unit, while the A11 Bionic chip is $5 more expensive than its predecessor.

By raising the base price for new iPhones, Apple is looking to keep its margins intact in spite of the increased cost to manufacture the device.