Titanium 3D Printing Video Might Be A Peek Behind The iPhone 16 Curtain

Apple is experimenting with manufacturing devices with the help of advanced 3D printing technology that might help reduce costs. Apple will start with an Apple Watch experiment that will include 3D-printed stainless steel components. If it's successful, Apple might move to 3D printing titanium parts. And that is great news for the future of the iPhone.

Apple already introduced its first titanium phones this year. However, it's exclusive to the iPhone 15 Pro models, and it won't be 3D-printed. In time, titanium might be used for more Apple devices. I hope the cheaper iPhone models will get the titanium treatment down the line.

There's no telling if and when Apple will start manufacturing iPhones with the help of 3D printers, but the video below shows the technology is already available to help manufacture complex devices that might be otherwise impossible to build using traditional methods.

We've heard several rumors detailing Apple's 3D printing plans for future devices without any visual depictions of how such technology would work. John Gruber shared a link to the following video that shows existing titanium 3D printing technology in action. It has nothing to do with Apple, but it proves the tech already works.

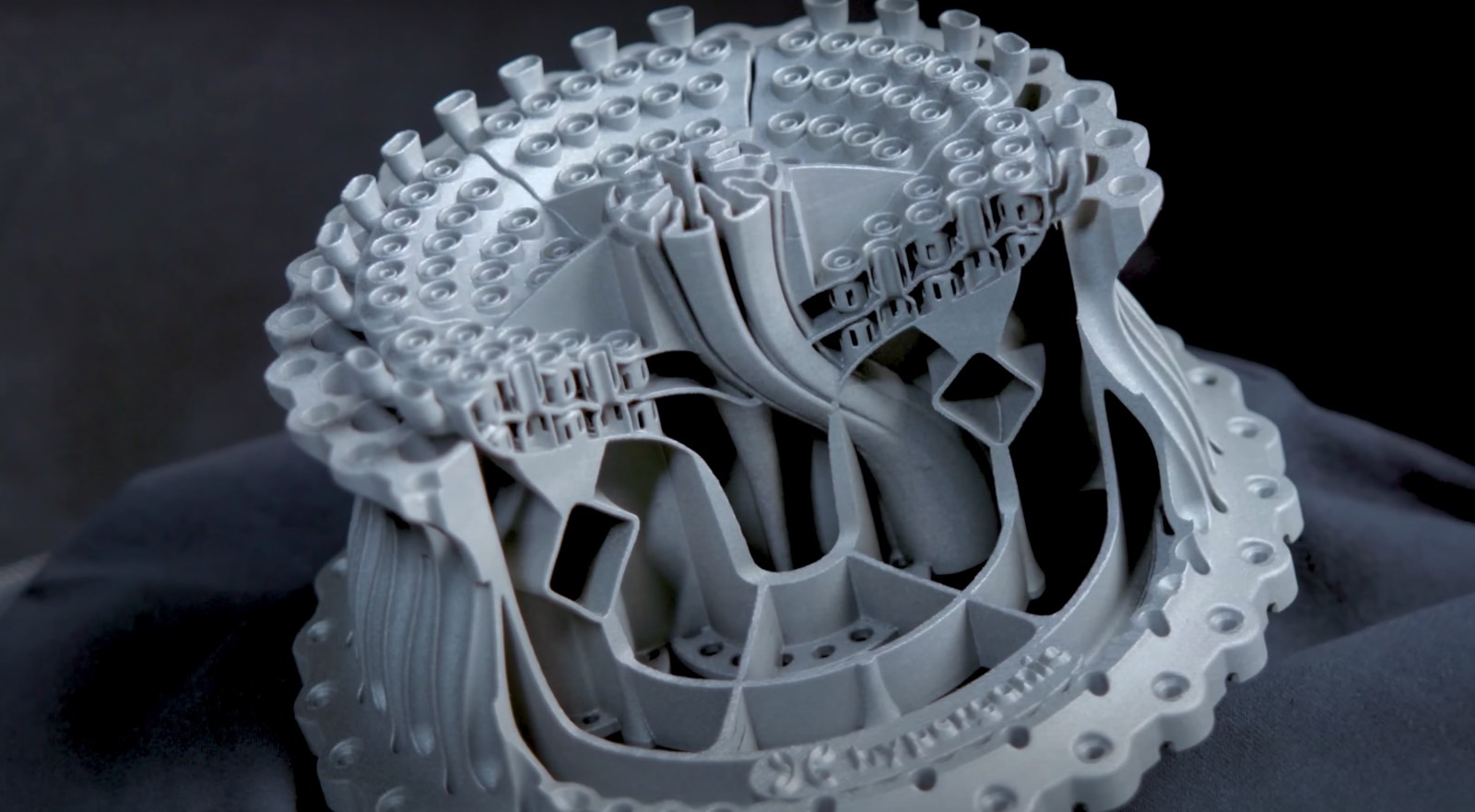

YouTube channel Titans of CNC Machining posted the clip about a year ago to show what's possible in the world of 3D printing:

The YouTubers used about 100 pounds of titanium and a dual-laser machine to 3D-print a complex part that wasn't even designed by a human. Artificial intelligence (AI) programs design the component, likely delivering a more efficient design than a human would. Mind you, that was before ChatGPT became a popular AI chatbot.

After setting everything up, the YouTubers let the machinery do its thing. The 3D printing job needed 48 hours to complete. The titanium component they made looks incredible, and it's flawless. The cutout in it is intentional, to show the intricate internal design of the titanium part. You wouldn't otherwise be able to see it.

What's also impressive is that the 3D printing job did not require any support to ensure the complex honeycomb-like structure was stable during the process.

It's clear it would be nearly impossible to manufacture a one-piece machinery like the one in the clip with traditional tools. And while the 3D printing process must be expensive, it certainly can be more efficient than other methods. You'd be able to save and reuse all the titanium powder that remains after the printing job is finished.

If Apple is using 3D printing to manufacture goods, it'll certainly make a point of it. Either during the upcoming iPhone 15 event or in the future, when it moves to 3D printing. And I think it's only a matter of time until we get there. After all, 3D printing an iPhone chassis seems a much simpler task than the print job in the video above.

The move to titanium gives Apple another point of differentiation between the non-Pro and Pro iPhones. However, as an iPhone 14 Pro user who might upgrade to the base iPhone 16 model next year, I'd love it if titanium would replace aluminum completely in Apple's lineup.

If it doesn't happen in 2024, then perhaps in the future. And, who knows, 3D printing might help Apple manufacture iPad cases out of titanium. Or MacBooks.

Remember that titanium is very durable, just like stainless steel. But, unlike stainless steel, titanium is much lighter. That's why the iPhone 15 Pros will be 10% lighter this year than their predecessors while packing a larger battery.

Until we get there, it'll be interesting to see if Apple says anything about its 3D printing endeavors this week. And whether the Apple Watch Series 9 will indeed fit 3D-printed stainless steel components.

While you wait, another video from the same YouTube channel shows the same hi-tech printer 3D printing a complex part out of stainless steel. Yes, it's just as amazing to watch as the titanium 3D printing job: