This New Alloy Could Be One Of The Keys That Lead To Limitless Energy

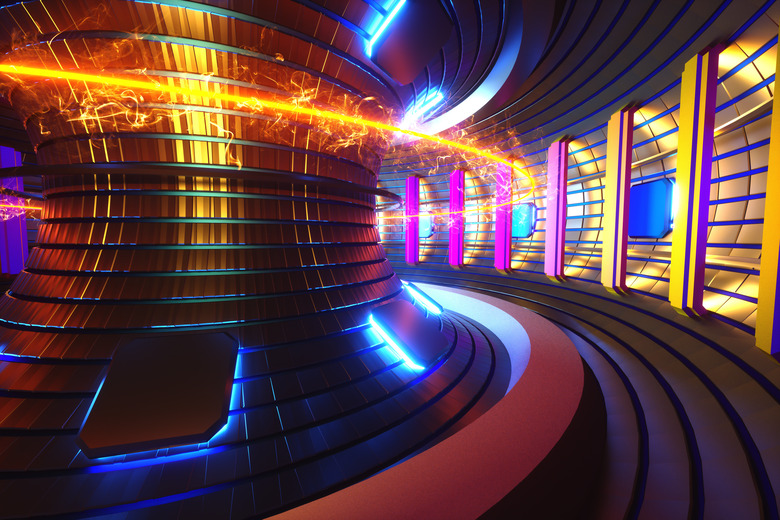

Nuclear fusion holds immense promise as a clean, limitless energy source. But building reactors that can withstand the harsh conditions inside them remains a monumental challenge. Now, though, scientists from the Institute of Science Tokyo have developed a heat-resistant alloy that could bring us one step closer to fusion energy.

The researchers published their findings in the journal Corrosion Science, highlighting how they began developing the allow from an existing alloy from the Kanthal family, known for its ability to endure extreme heat. The original alloy is made of iron, chromium, and aluminum. However, it was enhanced by dispersing tiny oxide particles—combinations of metals and oxygen—throughout its structure.

This process created what scientists call an oxide dispersion-strengthened (ODS) alloy. To further boost durability, the researchers coated the material with aluminum oxide, a substance known for its exceptional hardness and resilience. Altogether, this made a more heat-resistant alloy capable of resisting melting, corrosion, and structural breakdown at high temperatures.

In tests, the alloy was exposed to a molten lithium-lead alloy at a scorching 600°C (over 1,100°F). It emerged mostly unscathed. Further tests show that, remarkably, even without the aluminum oxide coating, the alloy formed its own protective layer during the test, contributing to its increased durability. This self-reinforcing property could prove invaluable in the demanding environments found in reactors.

Of course, you're probably wondering why 600°C matters when fusion reactors reach millions of degrees. The answer lies in the role that heavy liquid metal coolants like lithium-lead alloys will interact with the heat-resistant alloy within reactors. These coolants protect the reactor's walls and enable the creation of additional fusion fuel.

However, they're highly corrosive and slowly break down most materials they contact. The new alloy's resistance to such conditions makes it an ideal option for fusion reactors.

That's because Aluminum oxide, the coating's key component, is the same material that forms corundum, an industrial-grade mineral that becomes rubies and sapphires with certain impurities. This oxide is known for its exceptional hardness, and it plays a key role in the durability of the new heat-resistant alloy scientists created.

For fusion power to succeed, reactors need materials that last through extended, energy-intensive operations. This new alloy combines strength and resilience in a way that could extend reactor lifespans and bring us closer to achieving reliable fusion energy. With further development, this might just help shape the future of sustainable power.