NASA Broke The SLS Fuel Tank, But Swears It Did It On Purpose

NASA Space Launch System, the rocket system that will eventually provide the means for the space agency to send spacecraft and astronauts to the Moon, is a very big deal. The project has been in the works for a long time, and now that it's finally starting to come together, NASA wants to make sure it's ready for its time in the spotlight.

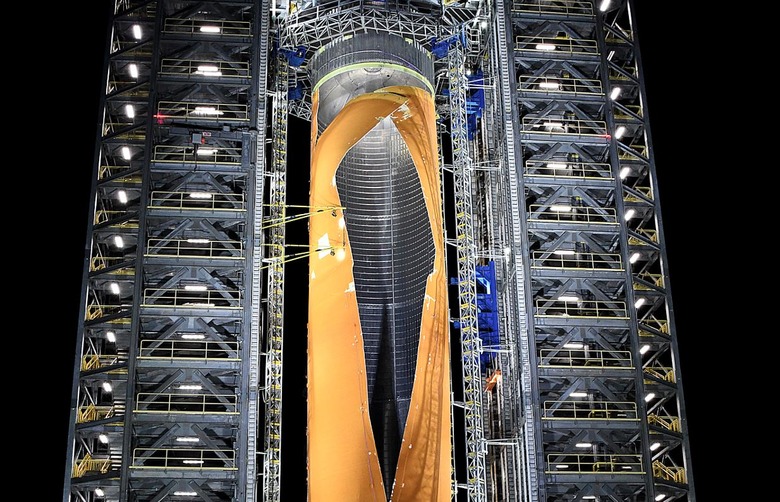

With that in mind, NASA recently put a version of the SLS liquid hydrogen fuel tank to the ultimate test, pushing it far beyond its designed limits. The test ultimately resulted in the failure of the tank, but that's exactly what NASA says it was going for.

"We purposely took this tank to its extreme limits and broke it because pushing systems to the point of failure gives us additional data to help us build rockets intelligently," Neil Otte, a chief engineer on the SLS project, said in a statement. "We will be flying the Space Launch System for decades to come, and breaking the propellant tank today will help us safely and efficiently evolve the SLS rocket as our desired missions evolve."

So just how well did the SLS tank stand up to the most punishing test yet? Pretty well, actually. According to NASA engineers, the tank withstood over 260% of the load stress it should ever have to deal with during a real mission. The tank maintained its integrity for over five hours before eventually failing.

Boeing, which is the primary contractor on the SLS project, performed its own stress tests on the tank prior to NASA's tests. Boeing's tests produced similar results, with the tank failing in roughly the same spot and within 3% of the failure load as observed in NASA's tests.