NASA's New Titanium Tires Can Never Get A Flat

Ever since man started thinking about putting things on other planetary bodies, transport has been a concern. Wheels are the obvious means of getting around, but using a standard air-filled rubber tire presents all kinds of problems in space — particularly, what happens if it pops a flat.

So the first moon buggy used metal wheels with steel springs, which provide the supple give of a tire without any need to contain gas. The problem is that steel springs degrade and plastically deform over time, meaning that the wheel starts to lose its shape. In the same way that a Slinky wears out over time, NASA's buggy wheels start to have problems with extended use.

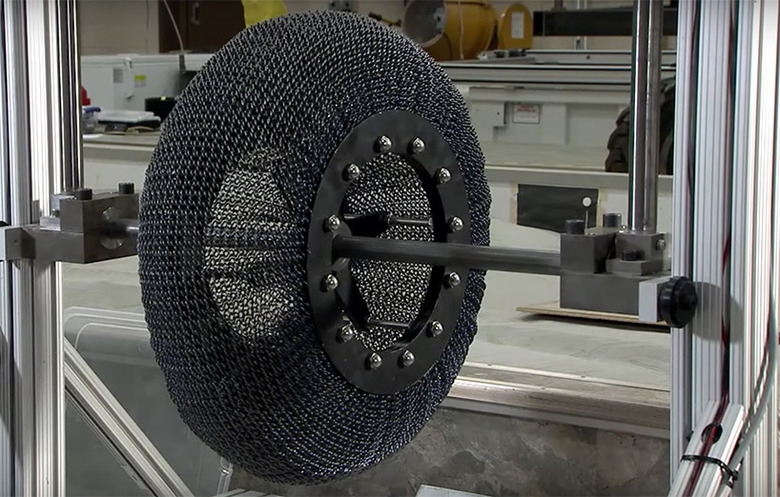

So, NASA took the original concept — a metal spring wheel — and brought modern materials engineering to bear. The result is a new type of metal spring tire, which uses a nickel-titanium alloy in place of steel. Instead of atoms deforming as the spring is moved, they instead re-arrange themselves as the tire is stressed. It's known as a "shape memory alloy," and means that the tire can be deformed virtually limitlessly, and still snap back to its original shape.

The technology is obviously intended for exploration of far-away planets, but it could have applications here on Earth. You can't exactly use a metal wheel on the highway and expect much grip, but a metal frame could (hypothetically) be coated with a higher-friction material to give a tire that's grippy and deformable for offroading, but with zero chance of a puncture developing.

In theory, different alloys could also be used to give the wheels different properties. The demonstration wheel showed off in the video below is clearly designed for offroading, but applying the same principle to a different structure and alloy could yield a much more practical wheel for use here on Earth.