Crazy New Process Uses Sound To Bond Metal And Wood Without Glue

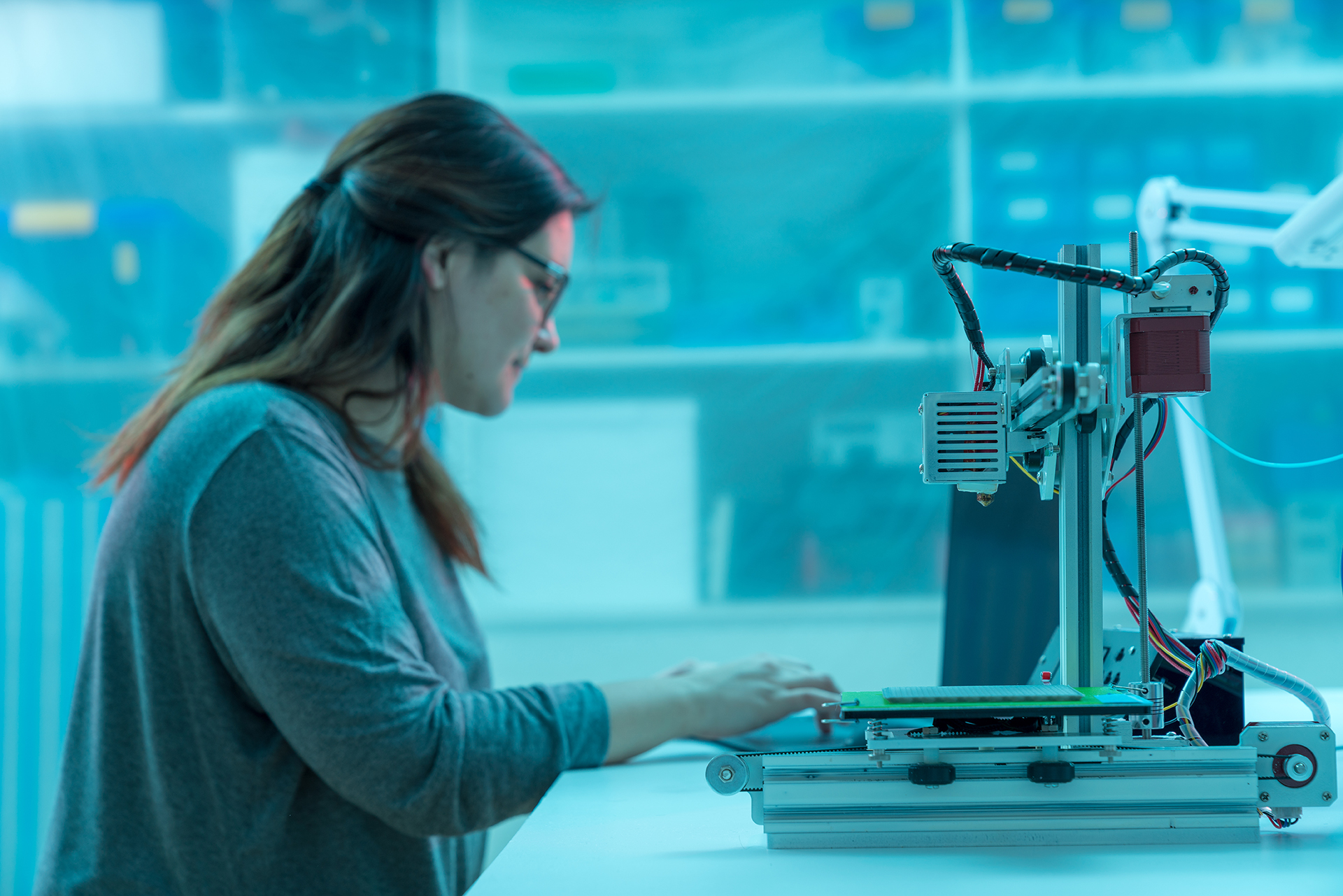

A new type of 3D-printed adhesive could change how we join materials together. So far, scientists have developed two new methods that can create extremely strong bonds at the pore level, eliminating the need to add additional glues to the bonding process.

While glues and other industrial-level adhesives are particularly strong at holding things together, they aren't great contenders for the environment. In fact, they often require massive amounts of energy and resources to produce. And while we have tried to create more eco-friendly options, these new methods take things much further.

In fact, the new methods rely on 3D printing to attach the items together at the pore level, which has led to the process being termed "AddJoining." Essentially, the different parts of an item are printed directly onto a piece of untreated wood, allowing the material to penetrate the pores. This creates a special type of 3D-printed adhesive.

When testing the strength of the new methods, the researchers involved found that when they snapped the bond, the adhesive portion itself didn't break. Instead, the fracture occurred in the wood and the polymer itself, not the joint. This means that creating 3D-printed bonds could be the future of how we adhere things together.

Further, the researchers believe that layering the 3D-printed adhesive on top of the wood that has been etched with a laser could help create much more complex structures and larger pores for the bond to sink into. This time, however, they wanted to keep things as simple as possible.

3D printing has proven to be really effective in multiple fields, including building entire houses. Perhaps future tests will help us see just how strong the bond can be, especially if the surface is etched with a laser before printing the component onto it. The researchers showcased their work at July's 7th IIW Annual Assembly and International Conference.